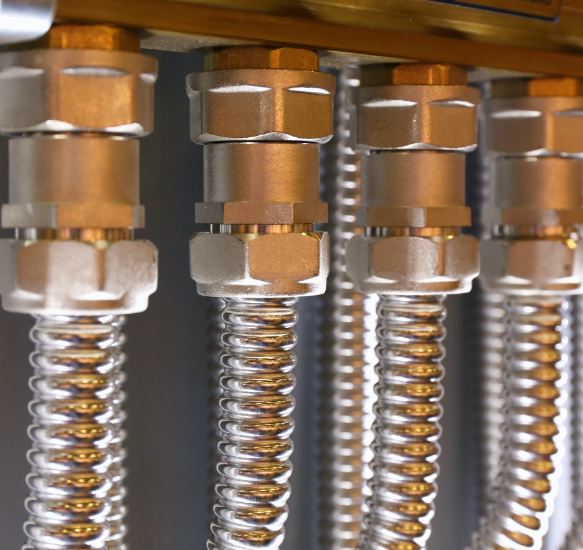

Metal Hoses

Made of stainless steel or high nickel alloys, used wherever flexibility and highest reliability are required, e.g. gas distribution systems in domestic, commercial and industrial buildings, solar and heating engineering, but also in the automotive industry, aerospace and in many other industrial applications.

BENEFITS OVER RIGID TUBES

Stresses in the pipe system may occur during assembly inaccuracies, thermal expansion, vibrations, and other pressure variations. To compensate for these unwanted stresses, a metal hose assembly provides the following advantages:

- No pipe ruptures due to fatigue

- No leaky flange connections

- No difficulty in replacing pipes having been deformed by high temperatures

SAVINGS IN ASSEMBLY/DISASSEMBLY

- Prefabrications of pipes require less precision

- No adjustment work needed on the hose

- Assembly inaccuracies are easy to correct

- Only part of the line must be removed

- Flexible elements are easier to remove and especially simpler to re-install

THE RESULTS

- Significant savings in assembly and disassembly of pipe systems

- Higher flexibility in designing the pipe guides and in case of any modifications