Welded Bellows

The welded metallic bellows has an unusual diversity of characteristics. It is both a mechanical mechanism and a hydraulic or pneumatic device.

In examining the possibility of a welded bellows in your application, consider the following list in a single mechanism, beginning with characteristics and ending with generalized applications:may occur during assembly inaccuracies, thermal expansion, vibrations, and other pressure variations. To compensate for these unwanted stresses, a metal hose assembly provides the following advantages:

- Piston and cylinder

- Spring

- Diaphragm / Capsule

- Hermeticity / Impermeability

- Self-protecting solid height

- Electrically conductive

- Extreme temperature capability – cyrogenic cold to jet engine hot

- High corrosion durability

- Torque transmitter

- Flexible reservoir

- Flexible conduit

- Flexible fluid isolator

- Aneroid

- Energy Absorber

- Actuator

- Vibration isoloator

- Fluid metering

ID / OD LIMITS

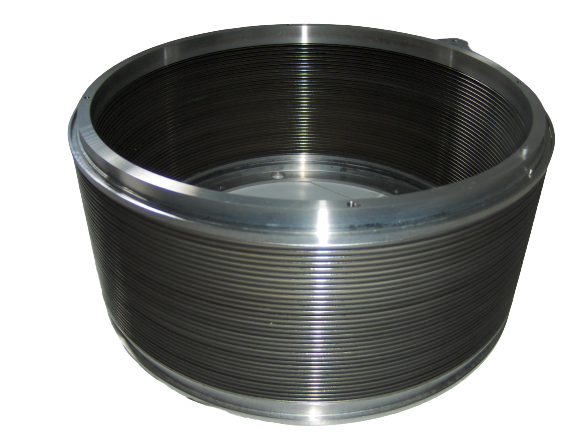

One of the great advantages of the welded bellows over the formed bellows is the ability to fabricate a welded bellows in virtually any ID/OD ratio. Since compactness is related to how much motion can be achieved in a given axial space, the more motion that can be derived from each convolution, the more compact the bellows. Available motion is related to the span of the bellows, or the distance from ID to OD. This characteristic is limited by the elongation of the material in the formed bellows—i.e., how much it can be stretched during forming before it ruptures. In the welded bellows, almost any combination of ID and OD can be punched. A bellows with a large OD and small ID, having a large span, will yield a high degree of axial motion per convolution. As with any technology, there are physical and practical limits for all characteristics. About the largest OD for a welded bellows is in the region of 20 to 24 in. At the other end of the scale, the smallest practical ID is currently in the region of 0.100 in., although the writer has built bellows with IDs smaller than 0.060 in.

LENGTH LIMITS

Welded bellows can be built very long with reasonably inexpensive tooling. It is not necessary to have intermediate attachments that waste space, as occurs with formed bellows; the welded bellows can be one continuous length. Bellows with a free length of 10 to 12 feet are not unreasonable.

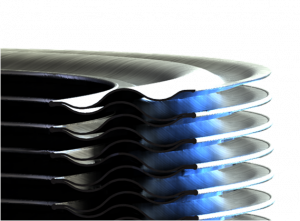

RIPPLES

One of the distinguishing differences between formed and welded bellows are the ripples that sweep across the span of the diaphragms. These can take various forms in which they either nest into one another or are in opposition, but the purpose is similar in all cases. Ripples help distribute stress more uniformly across the span of the diaphragm. In doing so, they can be used to alter the performance of the bellows—raising or lowering spring rate, helping to make spring rate more linear, enhancing pressure strength while retaining high stroke.