Analytical | Empirical | Advanced Design Tools

SYSTEMATIC PLANNING IS EVERYTHING. AND FOR MANUFACTURED PRODUCTS, PLANNING STARTS WITH DESIGN.

Flexial’s engineering capabilities are second to none, with linear and non-linear bellows analysis; fatigue analysis for life calculations; 3-D solid modeling using SolidWorks and Pro-Engineer ensures exacting component design; ANSYS and COSMOSWorks provide optimization of component integration and system performance.

With state-of-the-art parallel processing workstations, Flexial is capable of performing full non-linear analysis, plastic analysis, fatigue life calculations, structural, fracture critical, and vibrational analysis, and the integration of structural, thermal, and fluid for seamless analysis of our products.

SIMPLIFYING COMPLEX TASKS PROVIDES OPPORTUNITIES FOR INNOVATION

Flexial has designed some of the most complex bellows products in the marketplace, with high-technology components on the International Space Station, in the Ares J2X Rocket engine, on commercial and military aircraft, to sophisticated medical devices and gas-lift seals used miles under the surface of the earth.

ADVANCED DESIGN AND ANALYSIS TOOLS

PART OF AN ORGANIZATION-WIDE COMMITMENT TO SYSTEMATIC PLANNING AND EXECUTION, FLEXIAL CORPORATION HAS INVESTED HEAVILY IN THE UP-FRONT PROCESSES NECESSARY TO ANALYZE, MONITOR, AND MITIGATE RISK ON ALL OUR PROGRAMS.

DFMEA \ PFMEA

Design and Process Failure Mode and Effects Analysis

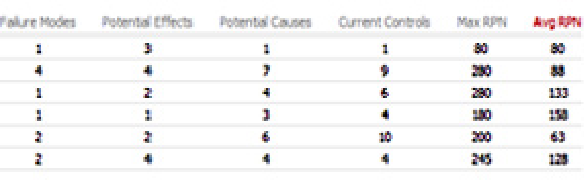

Flexial’s FMEA programs are unique – providing a digital, searchable library of identified failure modes that are continuously updated through lessons learned; internal and external failure mode analysis and systematic problem-solving methodologies that include detailed root cause analysis and corrective action; operator involvement through continuous improvement \ preventive processes, customer feedback, and field performance data.

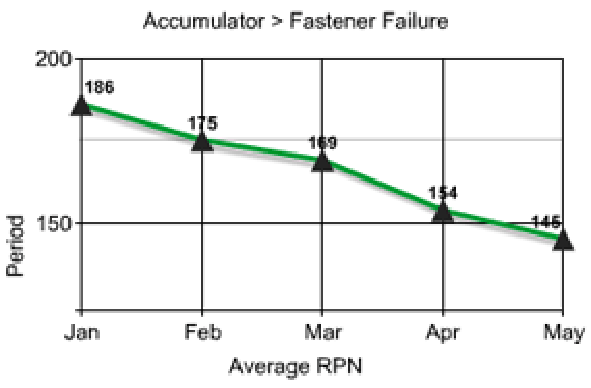

At any given moment, Flexial can identify, in a few clicks of a mouse, what the highest RPN (Risk Priority Number) in the entire operation is, or on a given process, or on a given design. In addition, Flexial has taken FMEA to a new level by making RPN numbers a key measurable – trending and tracking product RPN averages over time to ensure that we are continuously reducing risk with each product launch.

DMA

Flexial designs the process and the product concurrently, ensuring process capability for every specification. DMA aids prevention of downstream problems by identifying and correcting them in the design stage – the least-expensive way to solve a problem is before it happens.

CONCURRENT DESIGN

While Flexial designs the process with the product, Flexial’s engineers and program managers work concurrently with the customer to design products while the customer designs his higher-level system or subsystem. With everyone involved from the beginning, the chances of the resulting product perfectly meeting the customer’s needs are greatly enhanced. Manufacturing gets a product they are capable of building to the required quality and productivity levels, and the customer gets a product that meets or exceeds its expectations.

Trusted Partner for Technical Knowledge

Co-developed source control specification and design for:

• NASA’s Advanced Recycle Filter Tank Assembly

• Parker HSD A350 High Pressure Braking Accumulator

• Ratier Figac C-Series High Pressure Accumulator

First bellows vendor to supply and qualify all-titanium EHA for Parker Irvine F-35 EHA program

Reviewer and technical contributor to SAE International, A-6 Committee for new “C” revision of aerospace recommended practice ARP-4378; accumulators, hydraulic, cylindrical, aircraft, maintenance-free, factory pre-charged

Technical contributor to NASA Marshall Space Flight Center best practices and guidelines for NDE baselines to include welded bellows compliance to fracture critical hardware Parker A350 High Pressure Braking Accumulator per NASA-STD-5019