Fluid Management | Reservoirs | Surge Arrestors

TECHNICAL SPECIFICATIONS

- Temperatures from Cryogenic to 450° F (232° C) •

- Volumes < 0.1 milliliters to > 100 liters (25 gal.)

- Material from standard stainless-steel alloys to corrosion resistant high-nickel alloys and titanium.

- Design optimized for the application to meet system requirements, optimize weight, cost, and performance with up to infinite life.

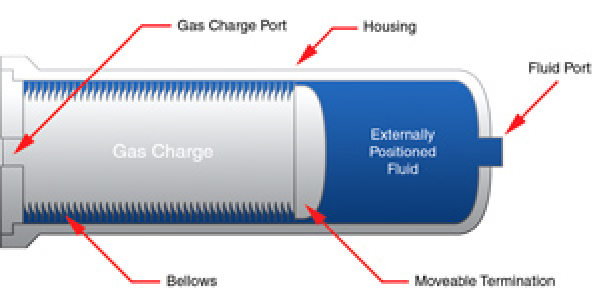

Welded bellows reservoirs, accumulators (also called volume compensators) and surge arresters differ in function, but share construction similarities. Each has an outer containment, an internal welded bellows separator and ports in one or both ends depending on the application.

The bellows, which serves as a flexible separator, is welded to one end of the containment and has a closed, movable end called a sweeper that slides through containment as the bellows expands and contracts with the system fluid. As needed for the application, the fluid can either be on the inside of the bellows or on the outside between the bellows and the containment with the gas on the opposite side.

KEY CHARACTERISTICS

All metal construction – hermetically sealed. Mass spectrometer leak tested with leak rates as low as 1×10-9 cc/sec/He.

Long shelf life – hermetic, all-metallic and maintenance-free design ensures a long shelf and operational life.

Compatible with all hydraulic fluids, coolant fluids, and a wide array of processing fluids including highly corrosive liquids.

Designed to minimize weight depending on the application. Product lines include all-titanium assemblies that are the lightest available.

Fast response time – low mass design ensures that accumulator responds instantly to slight pressure or temperature changes.

No installation restrictions – can be oriented in any position or direction without affecting performance characteristics.

Low long-term cost. Zero-maintenance and long life design eliminates failure modes and the significant costs associated with them.

DEVELOPING A NEW STANDARD FOR AEROSPACE ACCUMULATORS

Flexial Corporation has made aircraft, space, and military applications our principal focus. With ISO9001 and AS9100 certifications, our systems have been selected to produce products for Pratt & Whitney, Boeing, Raytheon, GE, Lockhead Martin, Hamilton Sundstrand, Rocketdyne, Honeywell, Northrup Grumman and many other aerospace primes.

FLEXIAL’S ACCUMULATORS ARE USED IN FLIGHT AND MISSION CRITICAL APPLICATIONS AROUND THE WORLD.

Related products currently manufactured by Flexial include the International Space Station Node 3 water storage system, aneroid sensors for the F15 and F16 fighter jets (F100 Engine), F22 Raptor avionics cockpit cooling accumulator bellows, Cooling Fluid Reservoirs for the Brite Star II FLIR, Fire Scout, Global Hawk, Rivet Joint and many other applications.

We have the engineering knowledge and resources, the manufacturing experience and capacity, a track record in this industry, and solid control of our programs to build your products on time the first time.

FLEXIAL BELLOWS ACCUMULATOR

- Compensates for thermal expansion of the liquid coolant

- Prevents fluid surges and pulsations

- Provides constant back pressure to preclude pump cavitation

DESIGN OPTIONS

- Active or static pressurization ports. Active ports allow system feedback for pressure modifications.

- Position Sensing: LVDT and potentiometers for active feedback or passive visual pressure and volume monitoring.

DIFFERENTIATING BETWEEN FLUID MANAGEMENT TECHNOLOGIES

RESERVOIRS

Reservoirs store fluid for delivery, either in a single surge or dispensed over time. The primary function is fill-then-dispense, as opposed to cycles of partial fill and drain. Reservoir delivery energy sources include:

- Permanently gas pressurized Charge gas sealed on one side of the bellows compresses during filling to store expulsion energy.

- Permanently liquid-vapor pressurized Volatile liquid on one side of the bellows partially evaporates; pressure builds up to phase equilibrium.

- Actively gas pressurized A regulated external pressure source supplies expulsion force. • Passively spring pressurized Delivery pressure is generated by the spring force of the bellows.

ACCUMULATORS

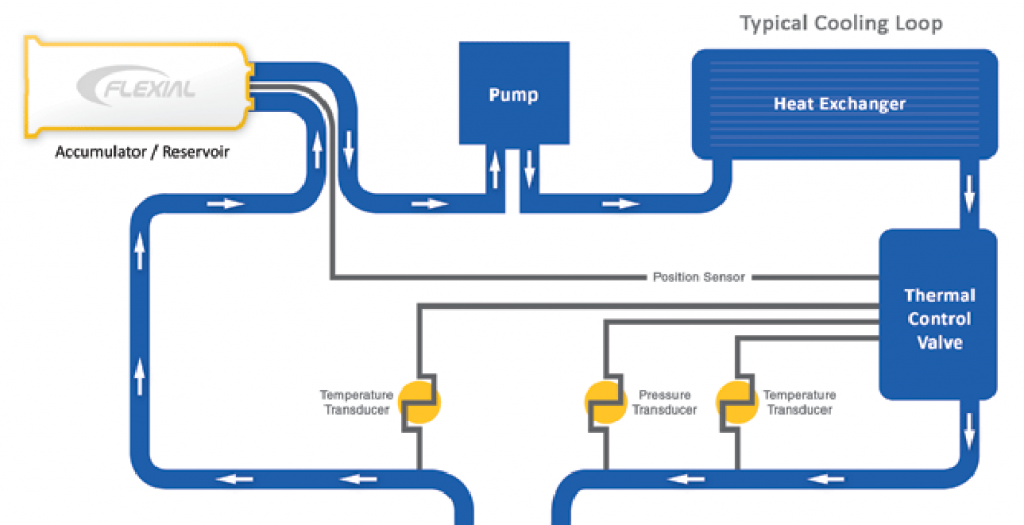

Accumulators are a type of reservoir that accept system fluid and returns it repeatedly. They usually have a fixed gas charge, are fully open to the system, and typically reside in closed fluid loops to perform one or more of the following:

- Bootstrapping/ Anti-cavitation Accumulator positioned immediately upstream from a pump surges fluid into the pump on startup to prevent cavitation. As system pressure and flow balance, the fluid is returned to the accumulator.

- Thermal volume compensation In a closed-circuit fluid system, the accumulator maintains a steady positive pressure by absorbing the temperature driven expansion and contraction of fluid.

- Pulsation absorption Accumulator placed immediately downstream from a reciprocating pump. Pulsations from the pump are attenuated by surging into the accumulator on the delivery cycle.

SURGE ARRESTORS

Surge arresters are a type of accumulator that includes an orifice between the bellows and the system and dissipates kinetic energy of a flowing liquid when the flow stream is suddenly stopped by a quick-closing valve.

The static gas charge is higher than the normal system pressure which keeps the bellows immobile and loaded against the fluid until hit with a surge. When flow is suddenly interrupted, the fluid diverts through the orifice and into the bellows, displacing the bellows and compressing the gas charge. The high velocity of this event causes heating of the gas charge and partial adiabatic compression that slows and stops the incoming surge.

The gas charge then pushes on the bellows and sends the surge back into the system. But now the orifice slows the return of the fluid while the wall of the arrester absorbs the heat of compression thus lowering the pressure of the gas. Usually this repeats for several decaying oscillations until the kinetic energy is dissipated, the system becomes static and the bellows is again loaded against the fluid.